Month: January 2014

Electron Microscopy

To conduct an experiment where the aim is to confirm if an controlled object follows the theoretical predictions, it is very important that the experiment do what you think it does, otherwise you cannot draw any conclusions.

There are a number of ways to design the microparticle ejector, and several parameters that will influence the results. Of course it is possible to do numerical simulations to predict the result, but because of the complexity, experimental methods will have to be used to confirm if the ejector works the way we want it to.

But how do you observe particles with individual sizes way below what you can view with your eye, and even a light-optical microscope?

The answer to this is electrons and the de Broglie wavelength, a formula derived in early 20th century by Louis de Broglie, telling us that all matter have a wavelength inversely proportional to momentum.

This awesome formula tells us that all matter not only acts like particles, it also exhibits properties of waves!

From the equation, we see that for an electron the wavelength can be made sufficiently small by increasing its momentum by e.g. accelerating it through a potential. This result, combined with a lot of other beautiful techniques such as electromagnetic lens systems and vacuum pumps, made it possible to manipulate “electron waves” in almost the same way as light waves in optical microscopes, creating the first electron microscopes in the 1930’s.

A Scanning Electron Microscope (SEM) is a common type of electron microscope, which will be used to analyze the particles from the ejector. Before being allowed to use the SEM, one has to go through some training sessions since there are so much things going on when using the SEM. After that, we will be able to confirm if the particles are separate or not, by actually looking at them. Technology ♥

About that optical observation

As mentioned in the previous post, a spectrograph is going to be built in order to confirm proper release of particles. Well, how will that look like?

At first we should take a look at how the spectrograph will help us. The scattering of the sunlight in the metal dust cloud will depend on the particle size. We have the geometry and the particle size, and we could with that information make a model of the expected spectrum. The task is then to compare the retrieved spectrum with the expected one.

One issue while designing the spectrograph will be the limited space inside the Free Flying Units lower part, after it got stuffed with all the bulky injection equipment. Below is an example of how a possible set-up of the spectrograph could look like. Another issue will be to decide which wavelength range the spectrograph must have. We already have a sensor (below) with a resolution of 2592×1944 pixels, so with a greater range, comes a poorer resolution.

When we have a prototype we will start doing tests together with the injection tests in the nice looking vacuum chamber. With a light source through the top window and the spectrograph recording from another, we will get a first picture of how the spectrum could look like. Stay tuned, and you will most certainly see how that will look like later on.

/The SCRAP team

Bachelor theses

Throughout the upcoming spring term, four bachelor students from the programme Engineering Physics at KTH will be doing their bachelor thesis projects as part of the SCRAP experiment. Three of these students are new to the SCRAP team and will hopefully be fully involved with the project as a whole. If they so choose, they may also continue working with the experiment beyond the completion of their theses.

The bachelor students and their respective theses are as follows:

- Hannes Lindström and Mikael Nivala Fernberg – Interaction between metallic microparticles and ionspheric plasma:

The project is about modelling the electrical charging and confinement of dust grains in the plasma. This will allow more insight into how the variation of involved parameters affect the outcome and lay ground for an optimal choice of material and size of the particles. - Joel Harsten – Optical observation of microparticles in the ionosphere:

This involves the design and construction of a spectrograph that will be used to optically detect the scattering of light on the particles. Since this cannot be detected from the ground, it is a key instrument to confirm proper injection and interpret radar observations. - Linnea Persson – Microparticle ejector for rocket experiment:

The spray approach to particle injection will be verified both numerically and experimentally in this project. The nozzle configuration, the particle-agent volume ratio and the required ejection rates are free parameters that must be chosen through testing to ensure a sufficient atomization.

As of yesterday, the work on the projects has officially begun. A presentation was given by the projects’ supervisors with a more detailed description on what the students will be doing and a tour of the facilities at the Alfvén Laboratory followed.

We welcome the new team members and look forward to a productive (and fun) spring!

/The SCRAP team

Project Management

A vital part of any project is the project management, this involves breaking down the milestones within a project, defining deadlines and making sure that people are following these deadlines. It also involves to keep track of what everyone is working on and how it all is progressing. We have created a weekly log system within SCRAP where each member reports what they have done during the week which makes this part of the project management easier. With the logs as guidelines, we have to be critical if we are keeping a good enough speed to meet our deadlines or if something needs to be addressed.

In SCRAP, the project management also includes planing the meetings, estimating a budget, sharing general information etc. The more comprehensive a project is and the more people involved the higher importance a working project management has for the progress and communication between the team members to work. Working in a real project of this size also teach you that project management could involve pretty much anything, from advising logo designs, picking up SCRAP Tshirts from a storage in the middle of nowhere and traveling to interesting REXUS events that sometimes due to extreme weather circumstances can ground you in Amsterdam for a couple of days.

In charge of the project management is the team leader Hannah Lindberg and assistant project manager Rasmus Bergström, both are also supported by the supervisors. Currently Hannah and Rasmus are focusing on putting the outreach plan into action, completing the project management sections in the SED and selecting which students to send to the Student Training Week & Preliminary Design Reviews (PDRs) 3-7 March, at SSC, Esrange Space Center in Kiruna.

Rasmus & Hannah at SNSB/ESA Selection Workshop, ESA/ESTEC, Noordwijk NL

Vacuum chamber progress

Have you ever wondered what happens if you get an Electrical engineering student, an Aerospace engineering student and a professor in space and plasma physics and give them a couple of wrenches and some time?

As have we! And we now know the answer!

One important aspect of our experiment is the distribution of particles into the atmosphere. At the moment we have two proposed delivery systems, one is delivery of particles via spray and the other is distribution via explosives. In order for our experiment to be success full we need to determine which of these approaches generates the most optimal distribution of particles. These delivery systems are going to be tested inside a vacuum chamber to determine which one spreads particles most effectively.

After two hours of work this is what you get.

Admittedly there is still some work to be done before the vacuum chamber can be used. We will of course inform you on our continuing progress.

/The SCRAP Team

Marcus leaves the team

I would like to thank all the members of the SCRAP-team for this time. I have now reached the end of my work in this project and move on to new and exciting endeavours.

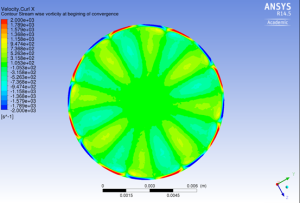

I have during my time in this project been working on analysing the spraying system. I have taken a look at how this problem can be simulated using CFD and have come up with a model that could be used to do a parameter sweep, to find crucial design parameters.

They say that you should finish with a bang so here are some nice colourful pictures from my simulations.

—————————————————————————————————————————————————————–

Bye Marcus! We will miss you.

/The SCRAP Team